Reverse Engineering

Recreating and Optimizing Mechanical Parts Through Precision Design

Recreating and Optimizing Mechanical Parts Through Precision Design

At DIME International Mechanical Engineering, we deliver comprehensive reverse engineering services tailored to the oil & gas, petrochemical, and industrial sectors. Our solutions address challenges such as obsolete parts, undocumented systems, and performance degradation—restoring equipment functionality and enabling design improvements.

Our approach delivers:

Typical applications include:

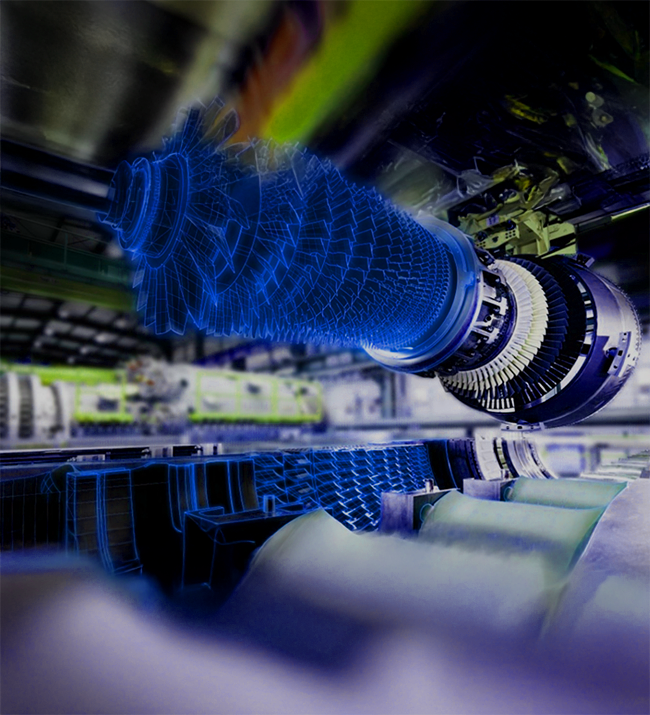

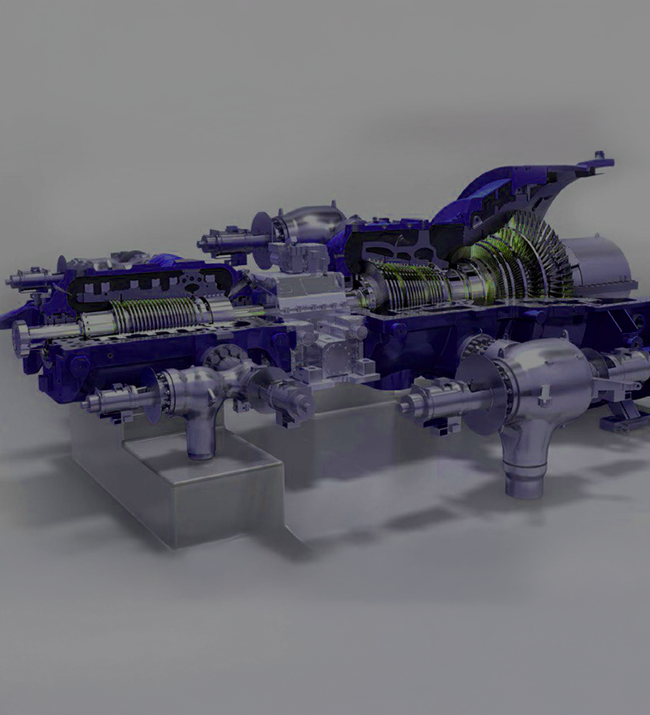

Our reverse engineering service is a multidisciplinary process—integrating research, design, manufacturing, and field testing. We handle every phase in-house to ensure precision, accountability, and performance consistency.

Our core process includes:

Strategic objectives:

We support a wide range of components for reverse engineering, including both mechanical and hydraulic systems. All re-engineered parts are manufactured to meet or exceed original specifications, with quality verified at each step.

Supported activities:

Typical products and spare parts we reverse-engineer:

We operate at fair rates for our services.

Consistent results through advanced blasting and coating technologies.

Long-lasting protection against corrosion and degradation.

Enter your search term and press search